Foams

At AJR Custom Foam our materials are domestically sourced from leading suppliers for reliability and quality

Our most used foams include, but are not limited to:

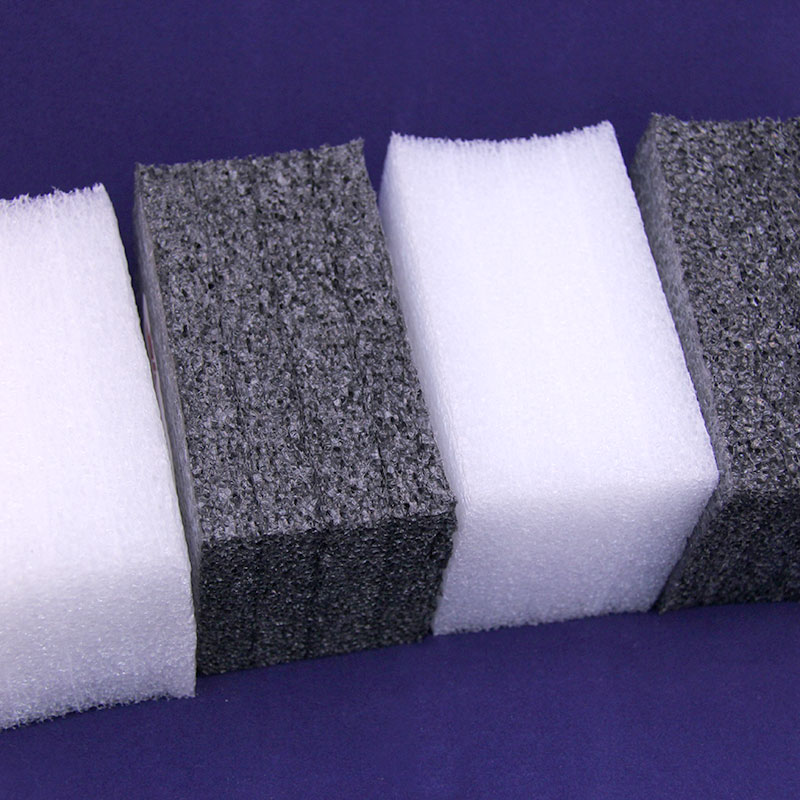

Polyurethane

Foam

Versatile, lightweight, resilient, flexible foam available with density, color, and firmness options

Widely used and ideal for seating, bedding, flooring pads, patient positioners, furniture cushions, case inserts, wound care, cleaning sponges, packaging, and toys

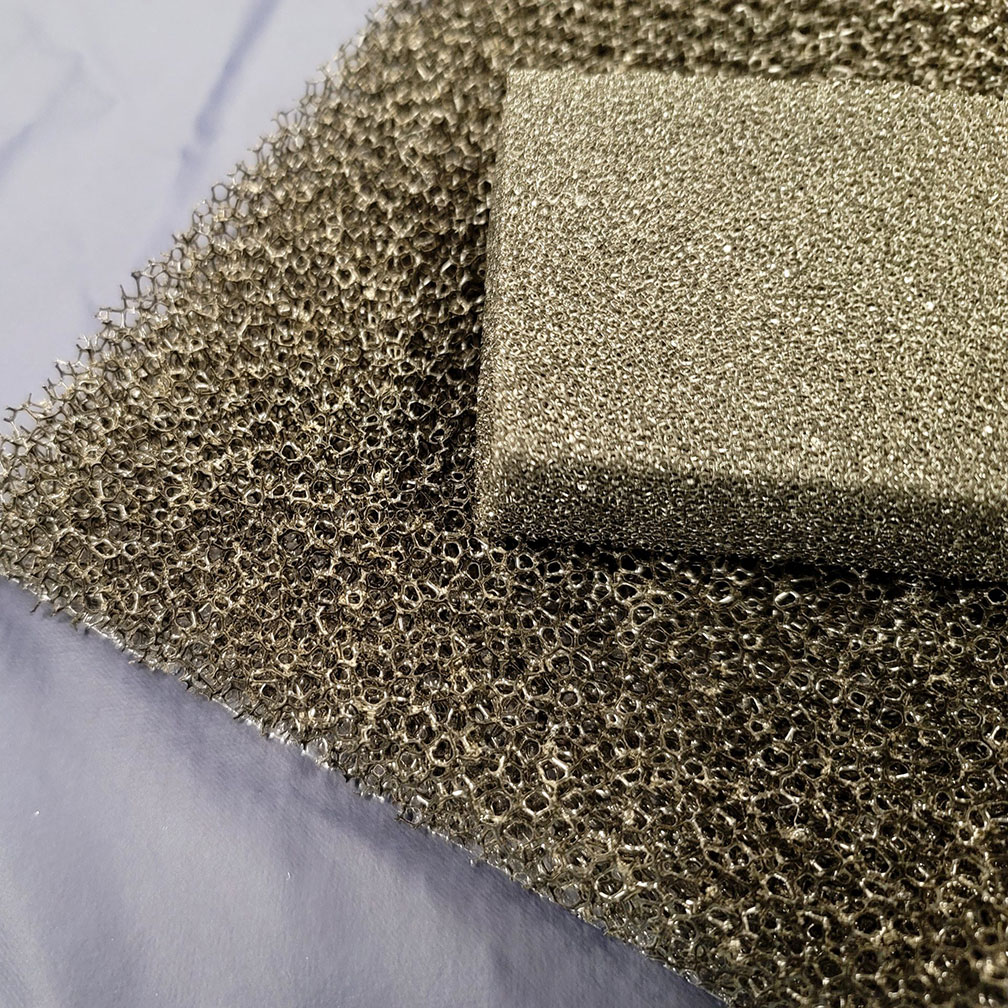

Reticulated

Foam

Open cell foam 10 to100 pores per inch (PPI), chemical and mildew resistant in many color options

Ideal for microphone windscreens, swabs, cosmetic applicators, NPWT wound care, cleaning wipes, humidifier pads, engine and other filter types, and cushions

Polyethylene

Foam

Durable, lightweight closed-cell foam highly resistant to chemicals, moisture, and mildew

Ideal for non-abrasive, shock-absorbent packaging, vibration damping, thermal insulation, case inserts, and flotation aids. Extruded into roll, plank and profile shapes

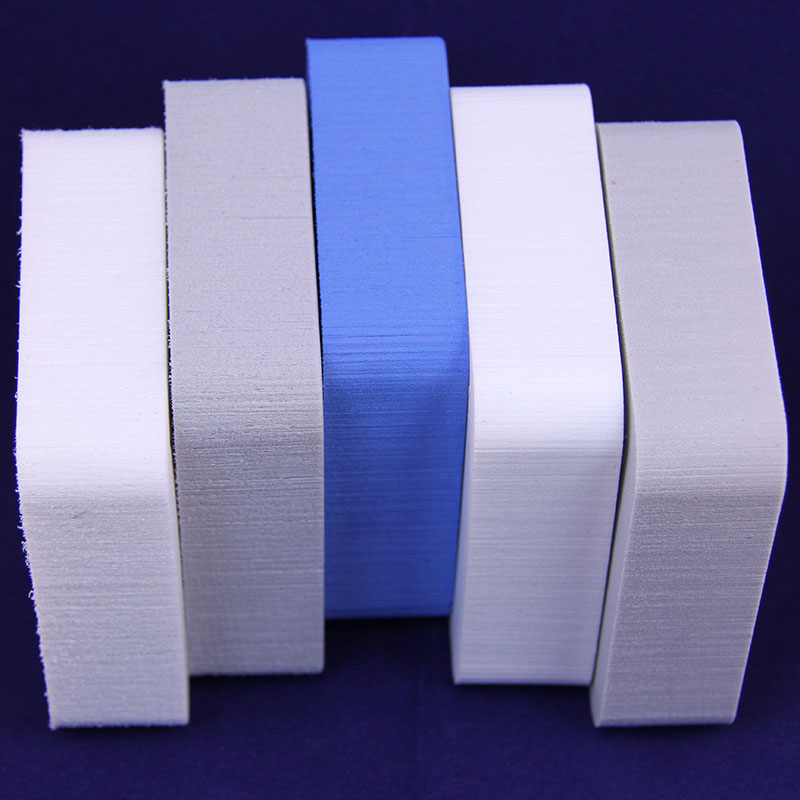

Cross-Linked

Polyethylene Foam

(XLPE) Closed-cell, water resistant foam with a compact feel, able to protect Class “A” surfaces

Ideal for orthopedic soft goods, medical device packaging, patient monitoring (EKG) devices, gaskets, sealing solutions, athletic padding, camping mats, and flotation

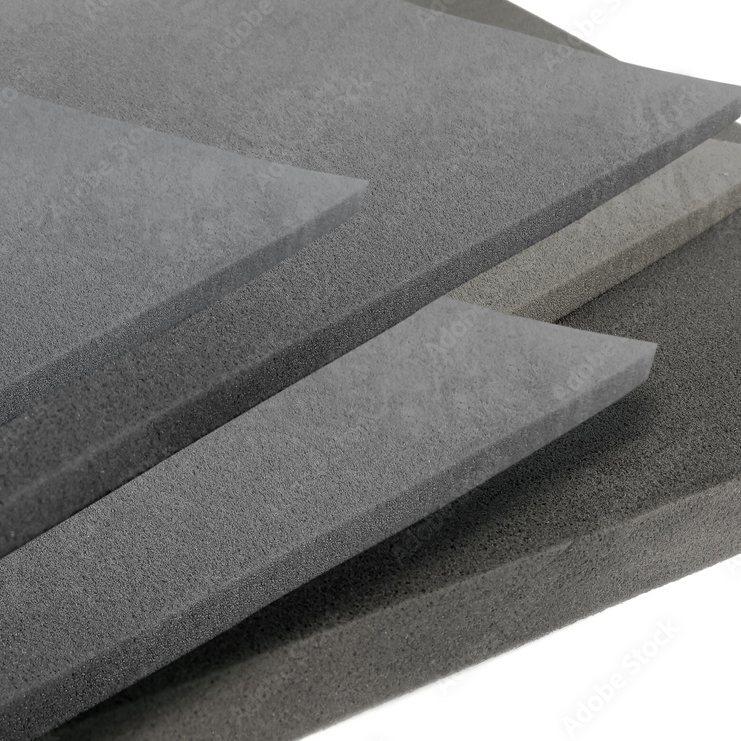

Low Permeability

Foam

Engineered to restrict air and water, excellent shape retention, and great for PSA lamination

Ideal for vapor seals and low-pressure liquid, dust and water-tight gaskets. Industry applications include air duct gaskets, appliance gaskets, and automotive AC gaskets

Visco Elastic

Foam

Slow-recovery resilient and flexible “memory” foam conforms uniformly to shapes

Ideal for furniture, mattresses, mattress toppers, pillows, neck supports, headrests, and wheelchair cushions, and shock and sound absorption